The rust removal process of a roller conveyor shot blasting machine can be summarized as: "high-speed impact, comprehensive coverage, and continuous operation." Its excellent cleaning effect on steel plates is mainly reflected in the following four key aspects:

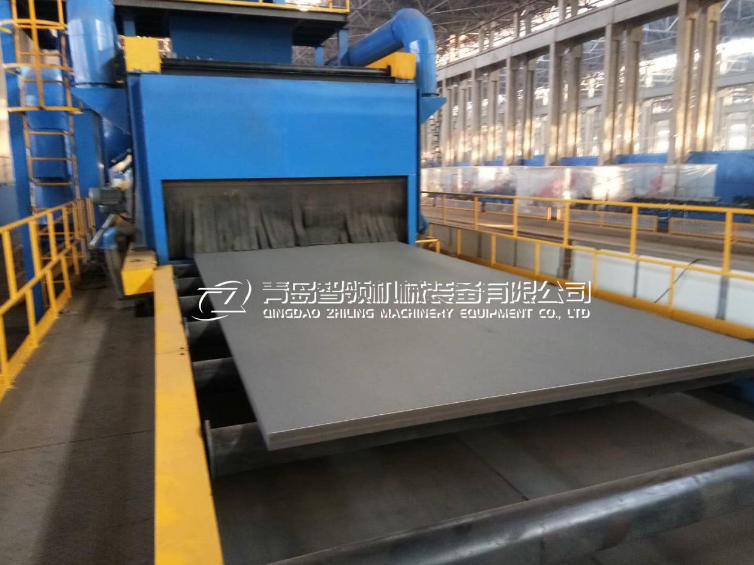

1. The roller conveyor shot blasting machine achieves all-around cleaning of the steel plate surface through a scientifically arranged shot blasting unit assembly. The shot blasters are installed on both sides and the top and bottom of the shot blasting chamber, simultaneously projecting steel shot to clean the steel plate.

This multi-angle impact design is particularly suitable for handling various complex surface conditions encountered in actual production. Whether it's ordinary flat areas, weld seams and joints left from welding operations, or corrosion pits and grooves formed over long-term use, all can be effectively cleaned under the dense abrasive impact. The steel shot and steel grit from different directions work together to create a thorough cleaning effect without dead angles, completely solving the technical problem of traditional cleaning methods' inability to handle complex surfaces.

2. Constant Shot Blasting Energy and Speed

Kinetic Energy Conversion: These high-speed abrasive particles possess enormous kinetic energy. When they impact the rust and oxide scale on the steel plate surface, the kinetic energy is instantly converted into impact energy, sufficient to break and peel off these deposits without damaging the base steel material (thanks to adjustable parameters).

3. Continuous and Uniform Conveying System

Roller Conveyor Drive: The conveying system consists of a series of synchronously rotating rollers, which smoothly lift the steel plate and pass it through the shot blasting chamber at a uniform speed.

Ensuring Uniformity:

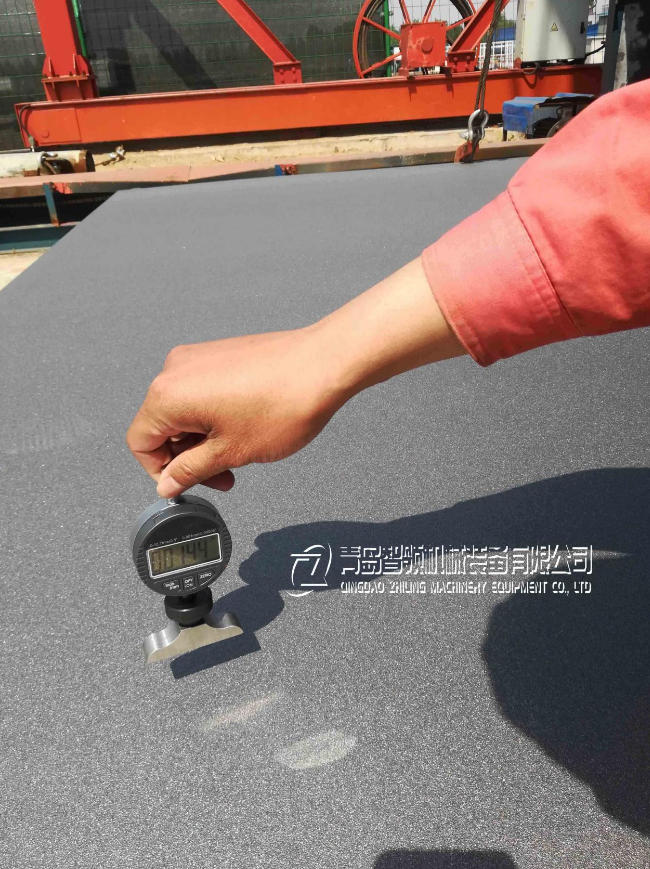

Constant Speed: The constant conveying speed ensures that every point on the steel plate surface receives the same shot blasting treatment time, thus avoiding over- or under-cleaning in certain areas.

No Deformation: The rollers uniformly support the steel plate, avoiding deformation that may occur due to suspension or single-point stress under high temperature or impact, making it particularly suitable for processing thin plates.

4. Efficient Abrasive Circulation and Sorting System

Recycling: The abrasive particles after impact, along with the removed rust and impurities, are collected via screw conveyors, elevators, etc. Air separation: The crucial air separator utilizes aerodynamic principles to separate still-usable whole abrasive particles from broken abrasive particles, dust, and fine impurities.

Quality assurance: Only clean, sized abrasive particles are returned to the shot blasting unit. This ensures:

Continuous cleaning efficiency: A constant supply of "sharp" abrasive particles for impact.

Good surface quality: Avoids secondary contamination or damage to the cleaned surface from impurities.