As a key equipment for surface treatment, the material selection of shot blasting machine directly affects the use effect and economic benefits. The following is a material selection scheme that has been verified in practice for your reference.

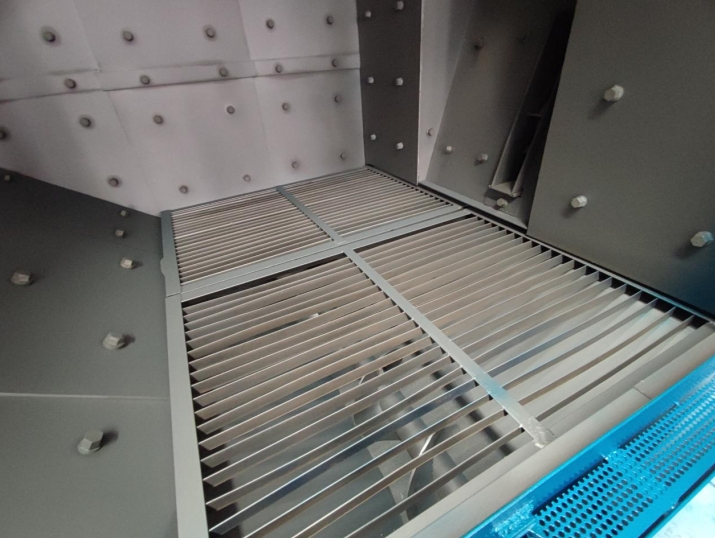

High manganese steel (ZGMn13)

Characteristics: Excellent impact resistance

Advantages: A hardened layer will be formed on the surface under continuous impact

Applicable to: Cleaning of large castings

Note: A running-in period is required for initial use

Wear-resistant alloy steel (NM400/NM500)

Characteristics: Hardness reaches HRC50 or above

Advantages: Outstanding wear resistance

Applicable to: Continuous working environment

Note: Welding process requirements are high

Rubber lining

Characteristics: Good buffering performance

Advantages: Effectively reduce noise

Applicable to: Thin-walled parts processing

Note: Regular inspection and replacement are required

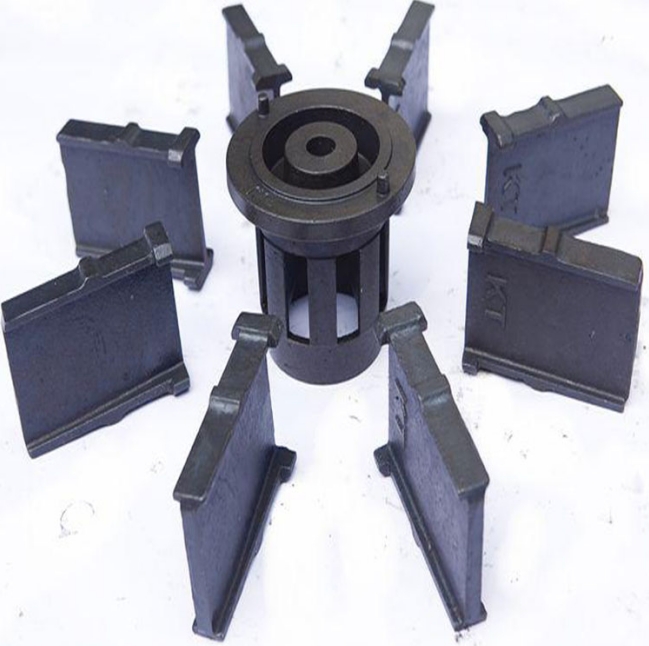

Shot blasting machine blades

Preferred: High chromium cast iron (Cr26/Cr28)

Characteristics: Hardness HRC58-65

Lifespan: Up to 5-10 times that of ordinary steel

Maintenance: 500-1 000-hour replacement cycle

Shot wheel assembly

Recommendation: Same material as blades

Purpose: Ensure wear consistency

Advantage: Extend overall service life

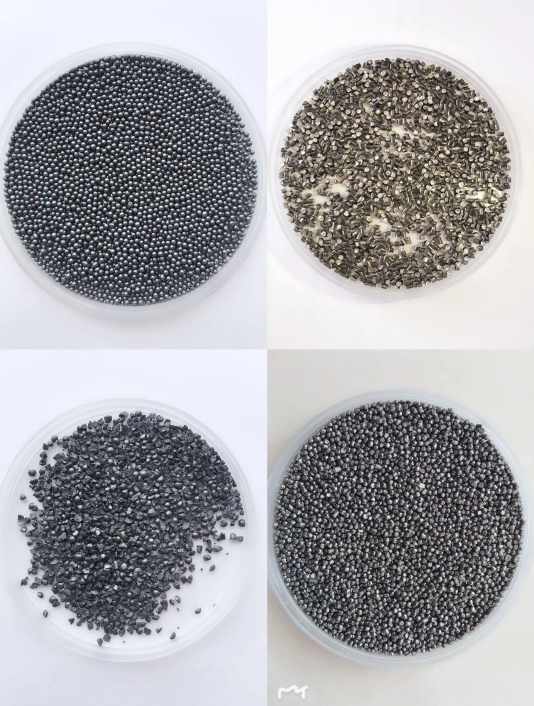

Conventional selection

Cast steel shot: Best value for money

Stainless steel shot: First choice for rust prevention

Wire cut shot: Efficient cleaning

Special needs

Ceramic shot: Precision parts processing

Glass shot: High requirements for surface finish

Economic configuration

Chamber body: NM400 steel plate

Blade: Cr26

Shot: Cast steel shot

Durable configuration

Chamber body: ZGMn13 composite structure

Blade: Cr28

Shot: Stainless steel shot

Corrosion-resistant configuration

Chamber body: 304 stainless steel

Shot: Ceramic shot

Regularly check the status of wearing parts

Maintain appropriate maintenance cycle

Adjust parameters according to working conditions

Establish spare parts replacement records