Shot blasting machines undertake high-intensity surface treatment tasks in actual production. Long-term operation will cause various forms of wear and damage to the shot blasting wheel, recovery system, dust collection device, and transmission mechanism. Effective maintenance requires accurate identification of the fault source and the rational scheduling of replacement and overhaul to minimize unplanned downtime and maintain stable treatment quality. The following provides actionable technical points based on the diagnosis-treatment-prevention process for reference by production site users and maintenance personnel.

First, distinguish between "performance degradation" and "functional failure." The former manifests as reduced cleaning efficiency and uneven surface finish; the latter manifests as equipment alarm shutdowns, feed interruptions, or dust collection failure. Common root causes include shot blasting wheel blade wear, directional sleeve deformation, separator screen blockage, lift mechanism obstruction, filter bag damage, and electrical component failure. Initial diagnosis can be made by observing operating noise and vibration changes, checking current curves and air pressure readings, and opening inspection hatches to visually inspect the shot blasting chamber and recovery channel. Perform a partial shutdown inspection of suspected areas, recording the location and extent of wear to inform maintenance decisions.

* Decreased Shot Blasting turbine Efficiency: First, measure the blade thickness and dynamic balance. If necessary, replace the blade set and perform rotor dynamic balancing. Also, check the clearance between the directional sleeve and the shot separator and adjust it to the designed value.

* Blockage in the Recovery System or Shot Flow Interruption: Clean dust and screens inside the separator, and inspect the elevator bucket and screw conveyor for wear and eccentricity. If conveyor components are severely worn, replace the bushings or spiral blades.

* Abnormal Dust Removal (reduced air volume or dust escape): Check fan speed and duct leaks, take samples to check filter bag integrity, and review post-filtration pressure differential records. Aging filter media should be replaced in batches, and dust accumulation in the ducts should be cleaned.

* Transmission and Electrical Failures: Check the axial and radial clearances of bearings, couplings, and reducers. Abnormal motor heating or current fluctuations require simultaneous inspection of the power supply and protection components. If a PLC or sensor alarm occurs, export the fault code and use the wiring diagram to locate the problem.

1. When replacing wearing parts, prioritize parts that match the original manufacturer's specifications. Record the batch and installation date to provide data for subsequent lifespan analysis.

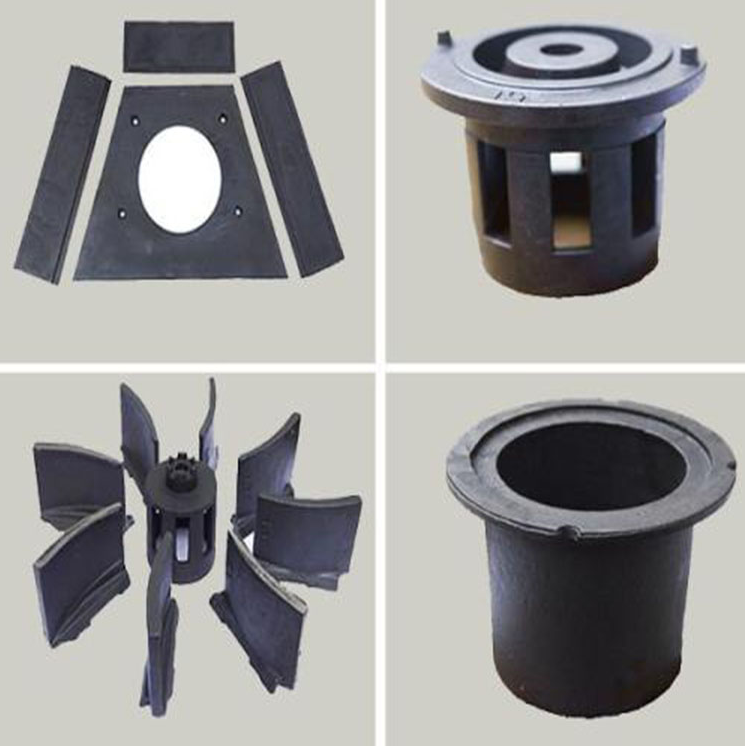

2. Implement the "complete replacement" principle for impellers and blades to avoid new dynamic imbalances caused by partial replacement.

3. Separator screening systems should have removable inspection ports to facilitate quick cleaning and replacement of screens.

4. Dust removal system maintenance should include airflow calibration and pressure differential curve recording to determine when to replace filter media.

Maintenance frequency should be based on actual load: Under continuous heavy load conditions, inspections of shot blast wheels and guards should be reduced to every few hundred hours. Under normal medium load conditions, inspections can be organized on a quarterly, semi-annual, and annual basis. A ledger should be established to record every replacement, repair, and abnormality, and monthly categorize fault types and downtime causes to develop improvement measures. This type of "data-driven maintenance" can effectively reduce spare parts inventory and improve response speed.

Professional manufacturers consider ease of maintenance and optimized wear resistance during the design phase. Reasonable shot blast wheel structure, easily replaceable guard plates, and easily accessible recovery channels significantly impact maintenance cycles and costs. As the equipment provider, we provide spare parts recommendations, maintenance manuals, and scheduled maintenance service options upon shipment. We also dispatch engineers to assist with on-site diagnosis and repairs when necessary.