Yes—a Wire Mesh Belt Shot Blasting Machine can handle thin or fragile parts when the machine is properly configured for belt design, blasting intensity, and part support. The determining factors are not the machine type alone, but how abrasive size, blast wheel power, belt speed, and part stability are engineered. Without these controls, thin parts can warp, dent, or collide.

Below is a practical, industry-based explanation to help you decide whether this machine type fits your parts.

Thin or delicate components are sensitive to:

High impact energy

Rebound collision with neighboring parts

Uneven support during transport

Thermal or mechanical deformation

Examples include:

Thin stamped steel parts

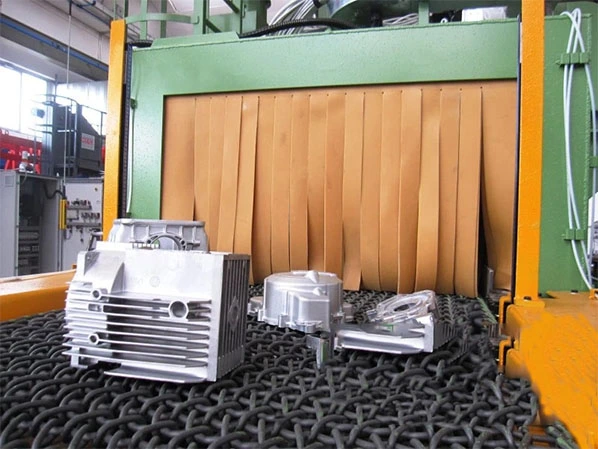

Aluminum die castings

Small welded assemblies

Perforated or slotted components

The blasting system must minimize impact while maintaining adequate cleaning.

A Wire Mesh Belt Shot Blasting Machine supports parts across their entire footprint, unlike roller systems that create point contact.

Protective design elements include:

Fine mesh openings to prevent part tipping

Reinforced belt edges to maintain flat tracking

Stable belt tension to avoid vibration

For fragile parts, belt selection is as important as blasting power.

Yes, by combining several adjustments:

Lower blast wheel power

Smaller abrasive size

Reduced abrasive flow rate

Optimized wheel angle

Increased belt speed for lighter exposure

These controls allow surface cleaning without excessive impact.

Abrasive choice is critical.

Common recommendations:

Small steel shot for smoother impact

Avoid large or angular grit

Maintain clean, well-classified media to reduce shock

Well-maintained abrasive reduces denting and edge damage.

Manufacturers achieve this by:

Limiting loading density

Using part separators or fixtures when necessary

Adjusting belt speed to prevent piling

A well-configured Wire Mesh Belt Shot Blasting Machine keeps parts moving steadily, not tumbling aggressively.

When evaluating a machine, look for:

Variable-speed belt control

Adjustable blast wheel frequency or power

Precision abrasive metering

Stable recovery system under the belt

Good visibility for process tuning

Manufacturers experienced with delicate parts will highlight these features proactively.

Despite its flexibility, this machine type is not ideal if:

Parts are extremely thin and flexible

Shapes interlock easily

Surface requirements are ultra-light cosmetic finishes

In these cases, alternatives like tumble belt or hanger-type machines may be more appropriate.

With correct setup, wire mesh belt machines are commonly used for:

Thin steel stampings

Light aluminum components

Small heat-treated parts

Delicate castings with uniform geometry

Success depends on process tuning, not just machine selection.

Before committing, you should:

Request sample testing

Provide part drawings and weight data

Discuss acceptable deformation limits

Confirm belt mesh and abrasive recommendations

A reliable Wire Mesh Belt Shot Blasting Machine supplier will encourage testing, not avoid it.

A Wire Mesh Belt Shot Blasting Machine can safely process thin or fragile parts when designed and adjusted for low-impact, controlled blasting. The key is understanding that belt support, abrasive selection, and blasting parameters work together as a system.

For buyers who focus on configuration rather than assumptions, this machine type offers both efficiency and part protection.