In modern sheet metal fabrication, servo-driven CNC turret punching machines are preferred for energy efficiency, precision, and high-speed punching, while hydraulic CNC turret punching machines remain suitable for heavy-duty punching with thick materials and high forming force requirements. The real difference is not only the drive system, but how each technology impacts production cost, accuracy, maintenance, and long-term flexibility.

Below is a practical comparison from an equipment selection and production efficiency perspective.

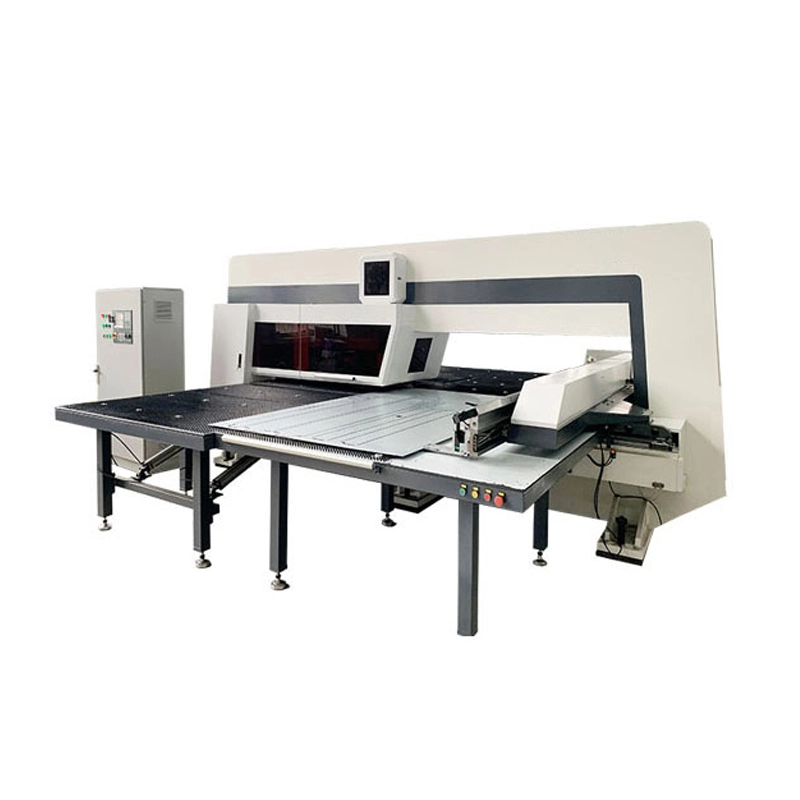

A CNC Turret Punching Machine for sale uses a rotating turret loaded with multiple punch-and-die stations to perform rapid punching, forming, and marking on sheet metal. The drive system—servo or hydraulic—controls how punching force is generated and applied.

This choice directly affects:

Punching speed

Noise level

Energy consumption

Maintenance frequency

Suitability for different materials and thicknesses

A servo-driven system uses servo motors and ball screws to generate punching force only when needed. Motion and force are digitally controlled with high precision.

A hydraulic system relies on hydraulic pumps, valves, and cylinders to provide continuous pressure for punching operations. Force output is stable and strong, especially for thick sheets.

Servo-driven CNC turret punching machines are significantly more energy efficient.

Reasons include:

Power is consumed only during punching

No continuous pump operation

Lower heat generation

Hydraulic machines typically run hydraulic pumps continuously, even during idle time, resulting in higher electricity consumption and heat buildup.

For factories with long operating hours, energy savings from servo systems become substantial over time.

Servo CNC turret punching machines deliver:

Higher positioning accuracy

Better repeatability

More stable stroke control

This makes them ideal for:

High-precision sheet metal parts

Complex hole patterns

Tight tolerance requirements

Hydraulic machines offer strong punching force but may show slight variations in stroke control due to oil temperature and pressure fluctuations.

Servo systems operate much more quietly because:

No hydraulic pump noise

Reduced vibration

Smoother motion control

Hydraulic CNC turret punching machines generate:

Pump noise

Valve switching noise

Higher vibration levels

In modern workshops focusing on operator comfort and noise control, servo-driven machines are increasingly favored.

Hydraulic CNC turret punching machines still have an advantage in:

Thick sheet metal

Heavy forming operations

Deep drawing or embossing processes

Hydraulic systems provide continuous and high forming force, which is sometimes necessary for demanding applications.

Servo machines can handle many forming tasks but may require higher-spec configurations for heavy-duty work.

Servo-driven machines:

Fewer mechanical components

No hydraulic oil

Lower risk of leaks

Cleaner operating environment

Hydraulic machines require:

Regular oil replacement

Seal and valve maintenance

Temperature management

Leak prevention

From a lifecycle cost perspective, servo CNC turret punching machines usually offer lower maintenance costs.

Servo systems integrate more easily with:

Automatic loading and unloading

Smart factory systems

Energy monitoring platforms

High-speed production lines

Hydraulic systems are reliable but less flexible for advanced automation and energy optimization.

| Application | Better Choice |

High-speed sheet metal production | Servo |

Thin to medium sheet punching | Servo |

Noise-sensitive workshops | Servo |

Thick plate punching | Hydraulic |

Heavy forming operations | Hydraulic |

Budget-limited projects | Hydraulic |

Key factors to evaluate:

Material thickness range

Production volume

Energy cost sensitivity

Noise requirements

Automation plans

Maintenance capability

Selecting the right CNC Turret Punching Machine should align with both current production needs and future expansion plans.

Servo-driven CNC turret punching machines represent the direction of high-efficiency, low-energy, and intelligent manufacturing, while hydraulic CNC turret punching machines remain practical for high-force, heavy-duty applications.

From an investment and operational standpoint, the optimal choice depends on balancing precision, energy efficiency, forming requirements, and total cost of ownership—not just machine price.