If your project requires high mobility, large-area surface preparation, and long continuous blasting runs, the vehicle-mounted Mobile Shot Blasting Machine is the better choice.

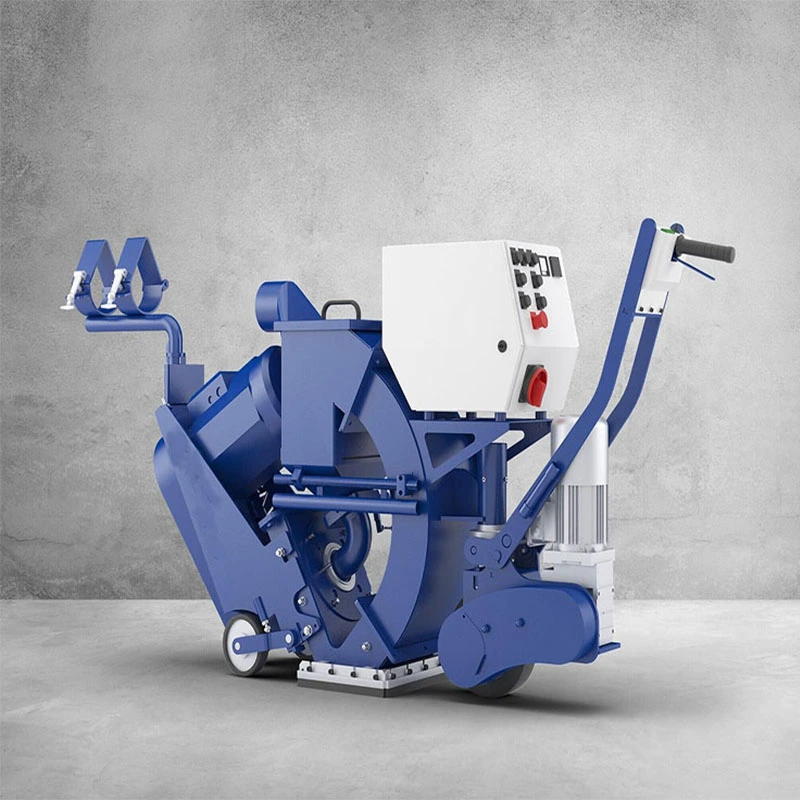

If your job focuses on small to medium areas, edge work, tight spaces, or indoor flooring, the walk-behind Mobile Shot Blasting Machine provides better control, flexibility, and cost efficiency.

Both machine types serve different market needs, and understanding their performance differences is essential for choosing the correct equipment for your flooring, highway, bridge deck, or industrial maintenance projects.

Coverage speed: up to 1000–3000 m²/hour, depending on blasting width.

Designed for expressway maintenance, airport runways, steel bridge decks, and long-distance industrial pavements.

Large hopper + automated abrasive circulation = continuous operation with minimal downtime.

Integrates with vehicle hydraulic power or independent generators.

Coverage speed: 150–400 m²/hour, depending on model and surface condition.

Best for factory floors, parking lots, warehouse resurfacing, ship decks, and small road sections.

Requires periodic abrasive refills and manual movement.

Expert Conclusion: For long, uninterrupted blasting tasks where speed determines project cost, vehicle-mounted machines offer far higher efficiency.

Google PAA often includes:

"Does shot blasting give a better finish?"

Maintain consistent travel speed via vehicle cruise control.

Large, stable blasting head ensures uniform surface profile across the full blasting width.

Ideal for demanding treatments like anti-skid enhancement on steel decks or runway preparation.

Operator-controlled speed can slightly fluctuate.

However, small blasting heads are excellent for:

Edges and corners

Narrow corridors

Precision blasting around drains or machinery bases

Expert Conclusion: Vehicle-mounted machines produce the most consistent macro-profile, but walk-behind machines provide better precision and local control.

One PAA question that often appears is:

"Is mobile shot blasting environmentally friendly?"

Equipped with high-capacity dust collectors (up to 30,000 m³/h extraction).

Designed for high-dust environments, such as highway rubber removal and steel deck rust removal.

Fully enclosed blasting chamber prevents airborne emissions.

Smaller dust collector capacity: typically 2,000–6,000 m³/h.

Perfect for indoor environments where dust sensitivity is high, such as:

Food processing plants

Pharmaceutical warehouses

Electronic manufacturing floors

Expert Conclusion: Both are environmentally compliant, but vehicle-mounted systems excel in heavy-duty outdoor dust conditions, while walk-behind units are ideal for sensitive indoor work.

Higher initial investment.

Lower abrasive consumption due to more efficient recycling.

Lower labor cost (typically only 1–2 operators).

Best ROI for contractors with large-scale or government maintenance projects.

Lower upfront cost.

Suitable for small contractors, flooring companies, and rental fleets.

Flexible for multiple small jobs across different sites.

Expert Conclusion:

Vehicle-mounted machines: Best for daily large-volume operations.

Walk-behind machines: Best for versatile, multi-purpose contractors.

Epoxy floor preparation

Warehouse and factory resurfacing

Parking lot renovation

Ship decks and container floors

Small road sections or patch work

Tight indoor spaces

Highways and expressways

Airport runways & taxiways

Bridge deck maintenance

Municipal road resurfacing

Large industrial plants

Long-distance anti-skid blasting

Expert Conclusion: Project environment and required mobility determine the correct machine choice.

Simple structure, easy maintenance.

Operators with minimal training can manage daily operation.

Lower wear-part cost (turbines, liners, dust filters).

More complex due to integration with:

Hydraulic power systems

Vehicle electrical controls

Larger turbine assemblies

Higher-capacity dust extraction units

Requires professional maintenance schedules.

Expert Conclusion: Walk-behind units are easier to maintain; vehicle-mounted machines require professional servicing but offer unmatched performance.

Walk-behind models are generally preferred because they handle edges, corners, and variable indoor terrain with better precision.

Yes. They are widely used on steel bridge decks and ship structures for rust removal and anti-skid textures.

No. Their abrasive capacity and mobility are not designed for long runs. Vehicle-mounted units are the correct choice for highways and runways.

No. When properly calibrated, it removes contamination without altering structural thickness.

Choose Walk-Behind Mobile Shot Blasting Machine if your work involves:

Indoor flooring and industrial facilities

Multiple small or medium-sized projects

Precision blasting around obstacles

Budget-conscious equipment investment

Choose Vehicle-Mounted Mobile Shot Blasting Machine if your work involves:

Long-distance blasting on highways or runways

Large-scale government or municipal contracts

High productivity requirements

Heavy-duty and continuous outdoor environments

Both machines play essential roles in the modern surface preparation industry. Your project volume, environment, and mobility requirements should guide the final decision.