Ensuring that your hook shot blasting machine is appropriately sized for your operations is crucial for maximizing efficiency, productivity, and cost-effectiveness. As an industry expert with years of experience in the shot blasting machine and sand blasting room industry, I will provide a detailed capacity checklist to help you determine if your hook shot blasting machine is the right fit for your needs.

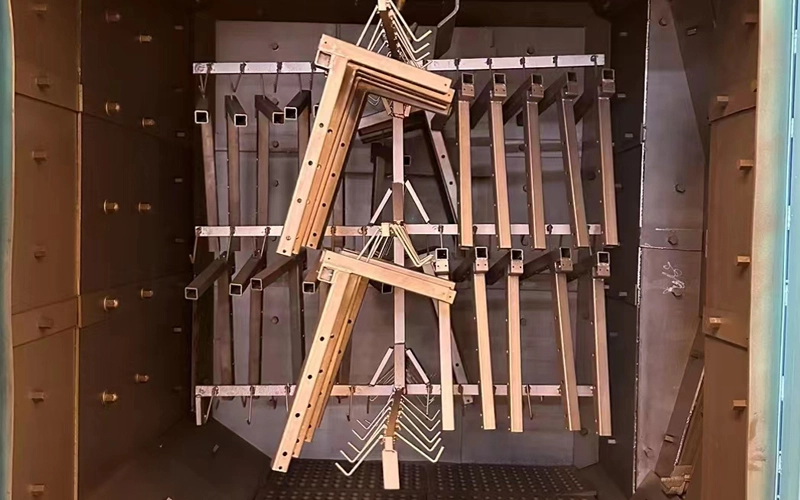

The first and foremost factor to consider is the size and weight of the workpieces you intend to process. Your hook shot blasting machine must be capable of accommodating the largest and heaviest items you plan to blast. Measure the maximum dimensions and weight of your workpieces and compare them to the machine's specifications to ensure a proper fit. An undersized machine may not handle larger workpieces effectively, leading to incomplete blasting and potential damage to the machine.

Assessing your production volume is essential for determining the capacity requirements of your hook shot blasting machine. High production volumes necessitate a machine with a larger blasting chamber and higher throughput capabilities. Calculate your average and peak production rates to ensure the machine can handle your workload without causing bottlenecks. A machine that cannot keep up with your production demands will lead to delays and increased operational costs.

Blasting cycle time is a critical factor that impacts your overall production efficiency. A machine with a shorter cycle time can process more workpieces in a given period, increasing your throughput. Evaluate the cycle time of your current operations and compare it to the capabilities of the hook shot blasting machine to ensure it meets your efficiency requirements. Faster cycle times mean higher productivity and lower labor costs.

The capacity of the abrasive media storage and recovery system is another important consideration. A larger media capacity reduces the frequency of refills and maintenance, allowing for longer uninterrupted blasting sessions. Ensure that the machine's media capacity aligns with your production needs to minimize downtime and maximize productivity. Insufficient media capacity can lead to frequent interruptions, reducing overall efficiency.

Power and energy consumption are significant factors that can impact your operational costs. A machine that is too large for your needs may consume more energy than necessary, leading to higher utility bills. Conversely, an undersized machine may struggle to meet your production demands, resulting in inefficiencies. Evaluate the power requirements of the hook shot blasting machine and ensure they align with your facility's capabilities and budget. Energy-efficient machines can significantly reduce long-term operational costs.

Maintenance requirements and potential downtime are critical factors to consider when sizing your hook shot blasting machine. A machine that is too large or complex may require more frequent maintenance, leading to increased downtime and reduced productivity. Conversely, an undersized machine may experience more wear and tear, resulting in higher maintenance costs. Assess the maintenance needs of the machine and ensure they align with your operational capabilities. Regular maintenance schedules and easy access to spare parts can minimize downtime.

Consider your future expansion plans when sizing your hook shot blasting machine. If you anticipate an increase in production volume or the introduction of larger workpieces, it may be prudent to invest in a machine with a higher capacity to accommodate future growth. This proactive approach can save you from the need to upgrade or replace your equipment in the near future. Planning for future needs ensures that your investment remains viable and cost-effective over the long term.

In conclusion, ensuring that your hook shot blasting machine is sized correctly involves a thorough assessment of several key factors. By carefully evaluating factors, you can select a machine that meets your current and future needs, maximizing efficiency, productivity, and cost-effectiveness. At Zhiling Machine, we specialize in providing high-quality hook shot blasting machines tailored to meet the specific needs of your industrial production. Our expertise in product operations and sales ensures that you receive the best solutions to enhance your operations and achieve optimal results. Contact us today to learn more about how we can help you size your hook shot blasting machine correctly and improve your surface preparation processes.